The Dawn of a New Era in Naval Engineering

The U.S. Navy just took a monumental step forward in modernization as Huntington Ingalls Industries (HII) unveiled the first-ever 3D-printed valve manifold assembly installed on the aircraft carrier USS Enterprise (CVN 80). This groundbreaking achievement represents not just an engineering triumph but a significant advancement in additive manufacturing strategies critical to shipbuilding.

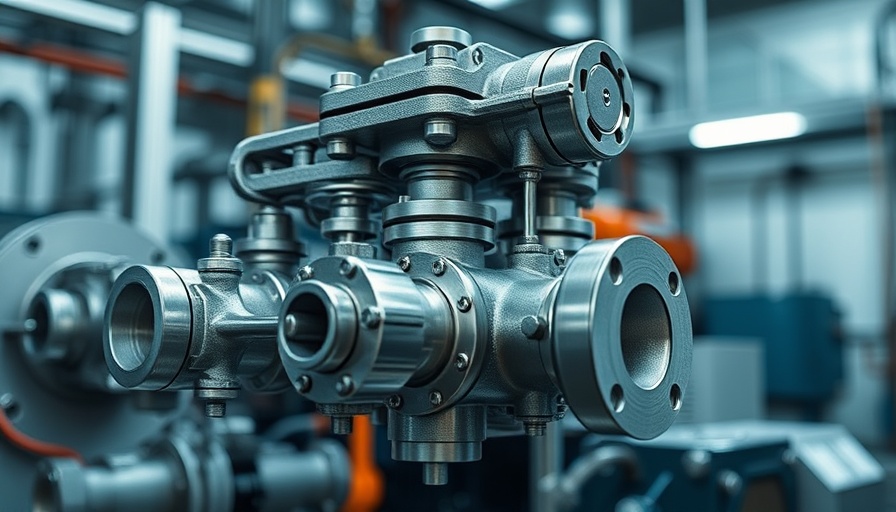

Located in a pump room, the valve manifold assembly measures around five feet in length and weighs approximately 1,000 pounds. This innovative piece of technology allows for the efficient distribution of fluids to multiple points onboard, demonstrating how 3D printing can enhance functionality and streamline processes.

Why 3D Printing is Vital for Modern Naval Operations

The adoption of additive manufacturing by the U.S. Navy does more than just leverage cutting-edge technology; it addresses the pressing challenges associated with global supply chains. Traditional manufacturing methods often result in lengthy lead times and logistical issues that can hinder naval readiness. However, using 3D printing can reduce production times significantly, enhancing efficiency and providing a quicker turnaround for critical components.

As noted by HII's Vice President of Engineering, Dave Bolcar, “What started as a proof of concept quickly turned into a tangible result that is making a meaningful difference to improve efficiencies in shipbuilding.” This sentiment encapsulates the optimism surrounding the integration of 3D-printed components in naval architecture.

Future Predictions: More Innovations on the Horizon

Looking ahead, HII aims to create at least 200 additional 3D-printed components for various naval vessels by 2025. The upcoming USS Doris Miller (CVN 81) is slated to feature similar 3D-printed parts, further solidifying the Navy's commitment to embracing innovation. This shift towards additive manufacturing could set a precedent for future shipbuilding practices, potentially accelerating the development and delivery of naval assets.

Innovations That Reshape the Supply Chain

For logistics managers and business travelers connected to the aviation sector, understanding these advancements is crucial. As the military enhances its supply chain efficiencies, allied businesses and global operations can mirror these practices to streamline their own processes. Collaborating with additive manufacturing technologies could empower local businesses to innovate, reduce costs, and respond more flexibly to market demands.

A Step Towards Sustainability in Defense

The lessening of material waste and reduced energy consumption in 3D printing compared to traditional manufacturing methods marks a significant movement towards more sustainable practices in defense manufacturing. As the world continues to prioritize eco-friendly solutions, the U.S. Navy is positioning itself as a forward-thinking leader in both military readiness and environmental responsibility.

As the implementation of 3D printing becomes more widespread within military operations, it is crucial for industries across logistics and supply chains to stay ahead of these trends. Being informed can lead to more adaptive business strategies in the fast-evolving landscape of defense technology.

For aviation professionals and business travelers who rely on a robust and reliable supply chain, understanding these changes fosters greater resilience and collaboration in operations both at sea and on land. Embracing these manufacturing shifts can drive future success.

Add Row

Add Row  Add

Add

Write A Comment